Optical Breadboards

25, 50 and 100 mm thick honeycomb breadboards offer the superior performance level of the

25, 50 and 100 mm thick honeycomb breadboards offer the superior performance level of the

broad banding and rigidity that effectively minimizes relative displacement in a wide frequency,

ensuring a promised performance and quality for a variety of purposes.

Features

Steel Honeycomb Core Structure

0.25 mm thick honeycomb steel layers are corrugated to increase its core density and minimize its cell size; These corrugated honeycomb steel layers are vertically epoxy bonded with stainless steel top skins, carbon steel bottom skins and sidewalls to offer static and dynamic rigidity for the outstanding performance level.

Steel Honeycomb Core Structure

0.25 mm thick honeycomb steel layers are corrugated to increase its core density and minimize its cell size; These corrugated honeycomb steel layers are vertically epoxy bonded with stainless steel top skins, carbon steel bottom skins and sidewalls to offer static and dynamic rigidity for the outstanding performance level.

Smallest Honeycomb Core Cells

Our honeycomb core yields in the highest core density and the smallest honeycomb cell size 3.2㎠, offering the remarkable rigidity of the optical tables. As the smallest honeycomb cells contributing to increase the elastic selection modulus, the natural frequency of the optical tops increases. Since our optical tops have the high natural frequencies, environmental vibrations are reduced, external forces are hindered to produce deflection and vibration isolation systems are effective. Moreover, the higher natural frequency minimizes vibration intensities and deflection under loads, which is critical for conducting optical experiments.

Spill-Proof Surface

Individual nylon cups are epoxy-boned under each mounting hole to prevent spilling of chemical or foreign substances into the honeycomb core.

Clean Surface with Mounting Holes

We delicately sand the optical table top surfaces to offer clean and non-glare work surfaces. M6 mounting holes are tapped on 25 mm centers for users to mount their applications on the optical table tops.

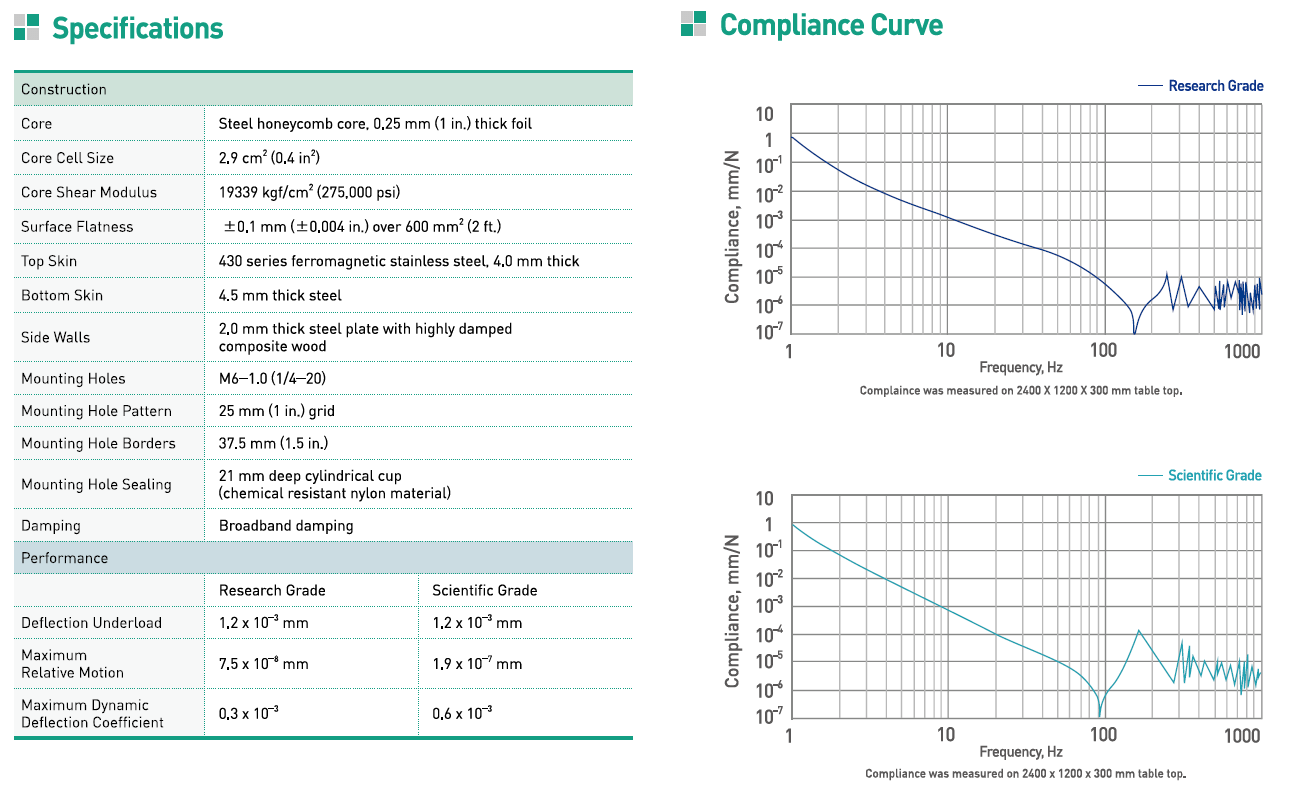

The primary goal of designing breadboards is to construct the breadboards as rigid as possible and we have proved that our honeycomb breadboards have been performing at the outstanding level through the data and the statistics. Our super rigid optical tops minimize relative motion through the structural damping (honeycomb structure). And, the honeycomb structure increases natural frequencies of the breadboards which effectively resists deflections and minimizes remaining vibrations that passes through the vibration isolation. The performance of our breadboards are measured by the compliance curve. The compliance curve indicates how the breadboards rigidly damp static forces (addition or movement of applications) and dynamic forces (environmental vibrations). As the compliance curve is closely related with the optical top performance level, our breadboards assures the maximum compliance level as the graph represents.

Optical Breadboard (Thickness 25mm)

Optical Breadboard (Thickness 100mm)

Optical Breadboard (Thickness 50mm)